Dale Cameron:

Canada’s only factory-trained

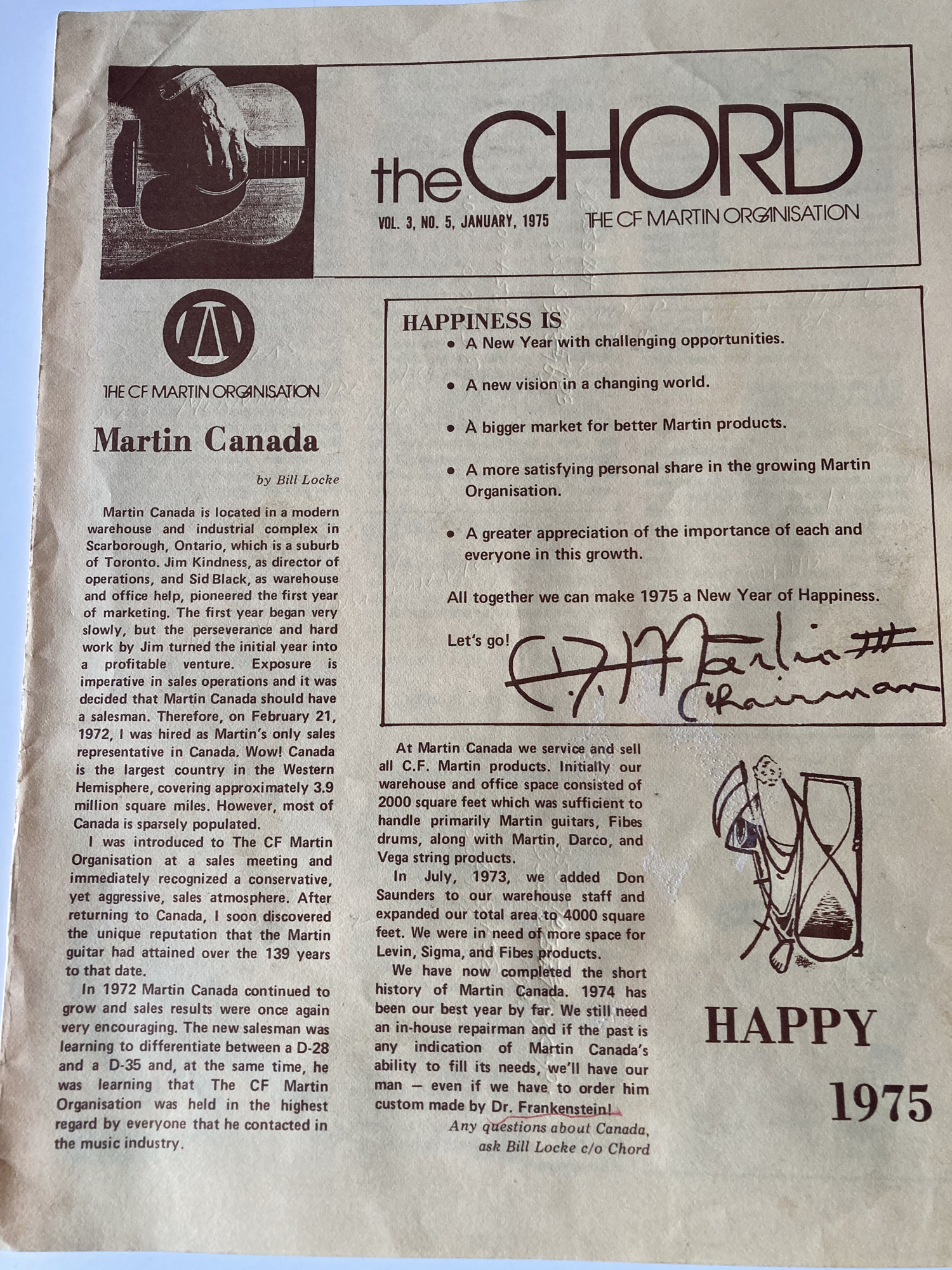

The following is an on-going project to compile and present a biographical history of Dale Cameron (b. 1952), Martin Guitar’s only factory-trained master craftsman in Canada.

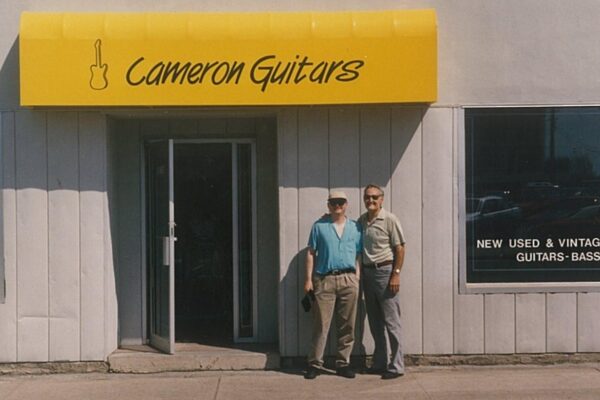

Throughout the 1970s, ‘80s and ‘90s, Dale had many encounters with musicians and others in the industry who sought out his services as a guitar master craftsman and repairman. He was also a successful businessman in Edmonton establishing and running his first repair shop and later Cameron Guitars for over 25 years.

Welcome

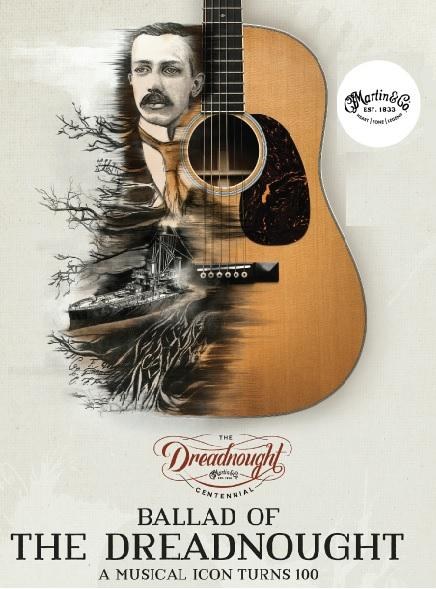

The Ballad of the Dreadnought

If you watch The Ballad of the Dreadnought you’ll see a direct link between my history and the originator of the Dreadnought shape and size of guitar.

His name was John Deichman and he was a very talented young man. Donald Dech apprenticed to John Deichman at the age of 16 and remained at Martin Guitar throughout his entire career apart from a stint in the Korean War.

I apprenticed to Donald Dech at age 23. If you think about it in familial terms, John Deichman is the grandfather, Donald Dech is the son, and I am the grandson of the Dreadnought guitar.

Thinking about that lineage now, leaves me awestruck. While there may be others with my kind of training, I believe there is likely to be very few. The reason for this is that by the ‘70s, Martin had adopted the Henry Ford assembly line model in both manufacture and repair. So you were trained at one station and not in all the rest.

Because I was going to be the head of the repair shop at Martin Canada, I needed to be trained in all steps of manufacture and repair.

During this time, Donald Dech was my teacher and mentor. His skill level was awesome. I’ll always be indebted to him for his guidance in the craft. Donald never held back any information or technique from me and scolded those who did.

Also, C.F. Martin III used to check on me every morning while I was training and occasionally caught me fooling around.

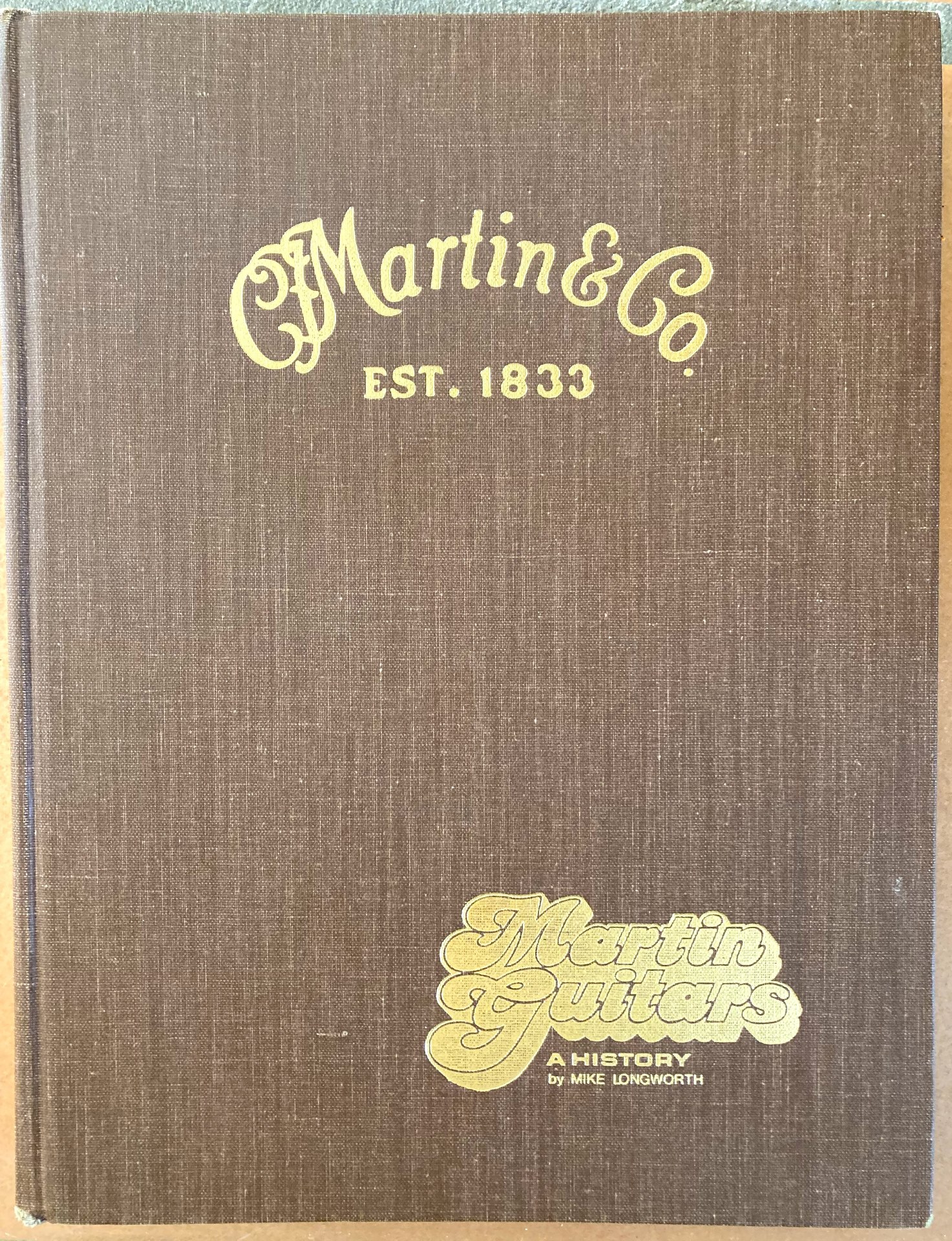

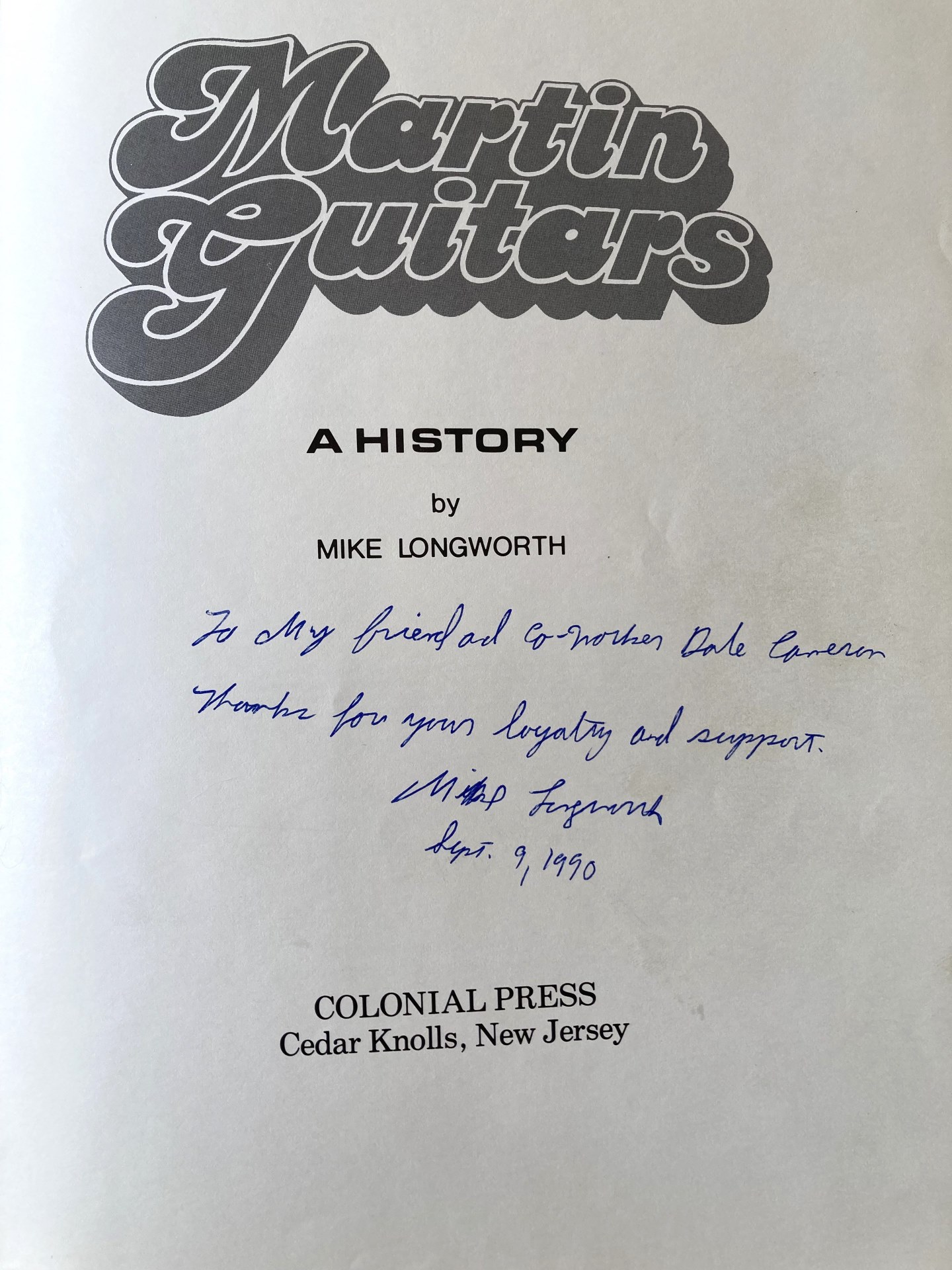

One of the definitive books on Martin & Co. is by Mike Longworth. Dale worked with Mike and has an inscribed copy at home. It reads:

To my friend and co-worker Dale Cameron

Thanks for your loyalty and support.

Mike Longworth

Sept. 9, 1990

Click here for a link to the book which you can freely read on Archive.org, much like your local library.

VIDEOS

The Ballad of the Dreadnought

This short documentary from 2016 provides an overview of the 100 year history of the Martin Dreadnought and its contribution to music and culture.

Gibson Flying V’s and other things: Robin Hunter

recounts working at Cameron Guitars

In the three video clips (transcript) below, Vancouver-based guitarist and songwriter Robin James Hunter discusses getting hired by Dale Cameron and learning the ropes at Cameron Guitars in Edmonton.

Hunter, who along with writing and performing his own songs, has worked as a guitarist for some of Edmonton and Vancouver’s most loved music artists. Devilsplender, Parkland, Mark Davis, Sarah Wheeler, Sherry Lee Heschel, Sound Refuge, Wendy Mcneill and many others have all added his talents to their live and recorded legacies. He founded the bands World War Three D and The Imagineers.

Dale (who was an honorary member of The Imagineers and played slide for their Rosie Award nominated movie soundtrack “Two Brothers, a Girl and a Gun”) and Robin were bandmates in the Sherpas of Love in Edmonton.

CLIENT REPAIRS

Here’s a partial list of notable client repairs made by Dale over the years:

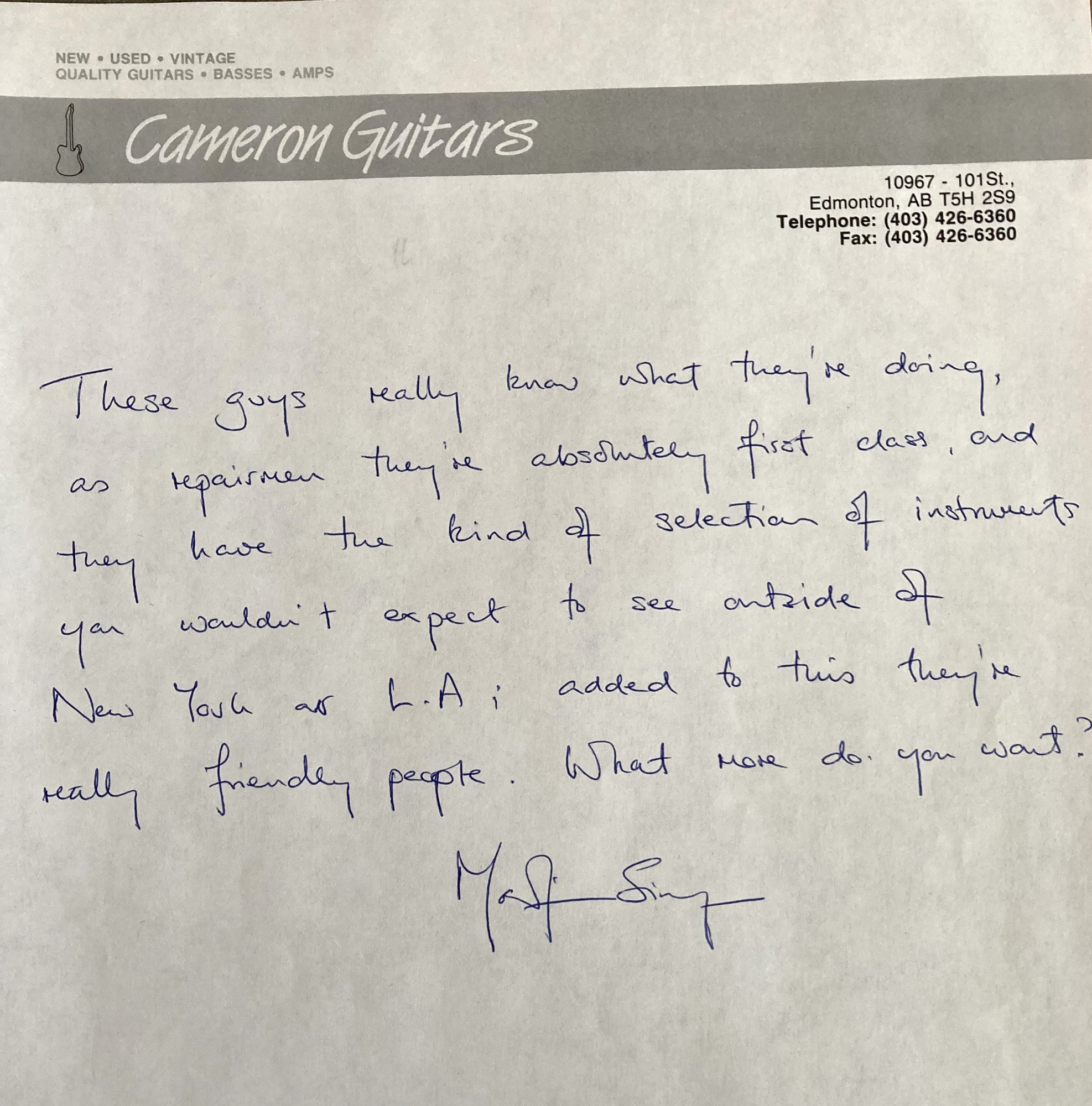

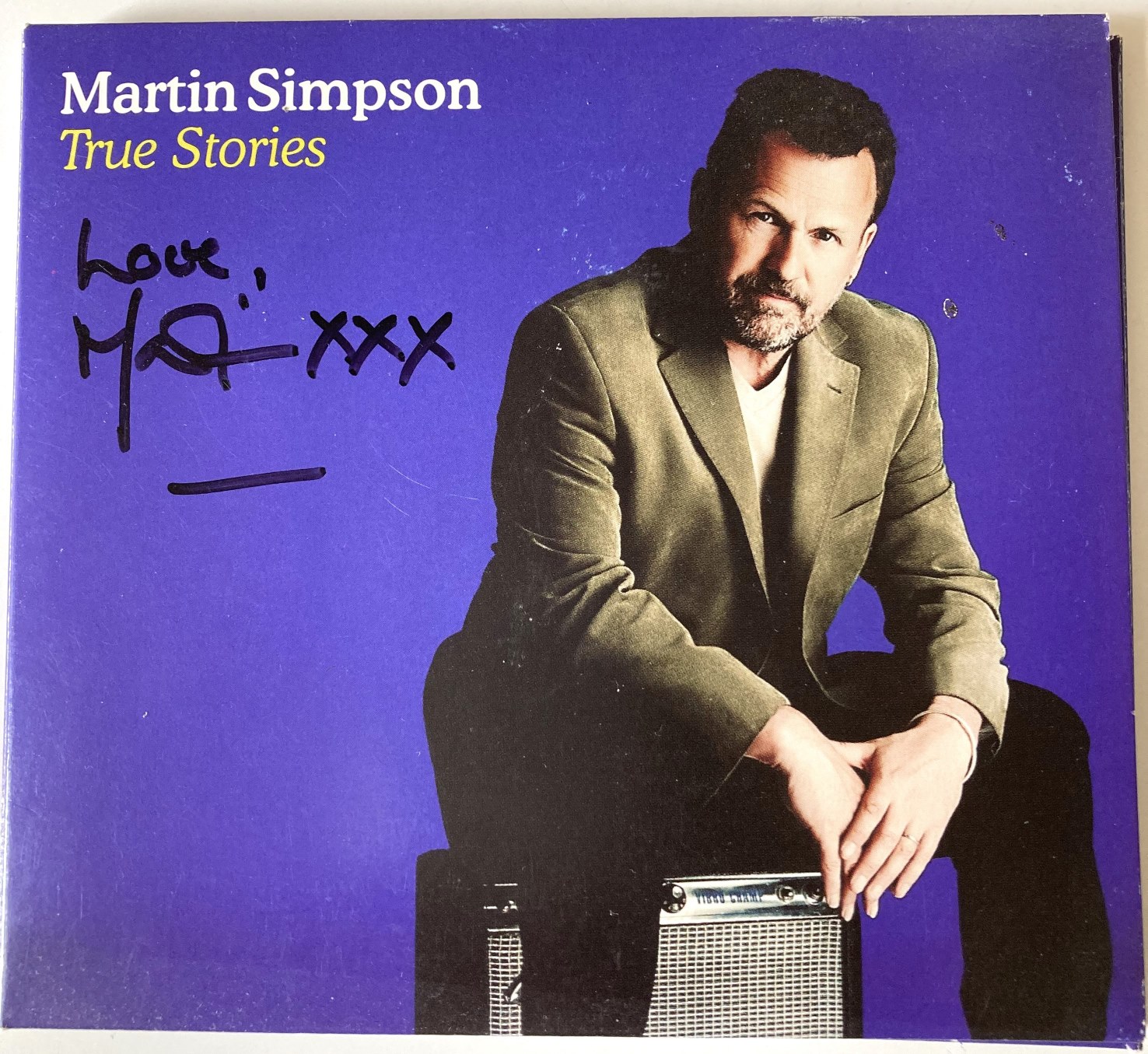

Martin Simpson, British fingerstyle guitar player, whom Guitar Player once touted to be in the top ten best guitar players in the world. Can’t recall guitar maker – action adjustment.

Redd Volkaert, a Canadian Fender Telewhacker and Grammy winner from Vancouver who wound up playing for 10 years with Merle Haggard. Various telecasters, various repairs.

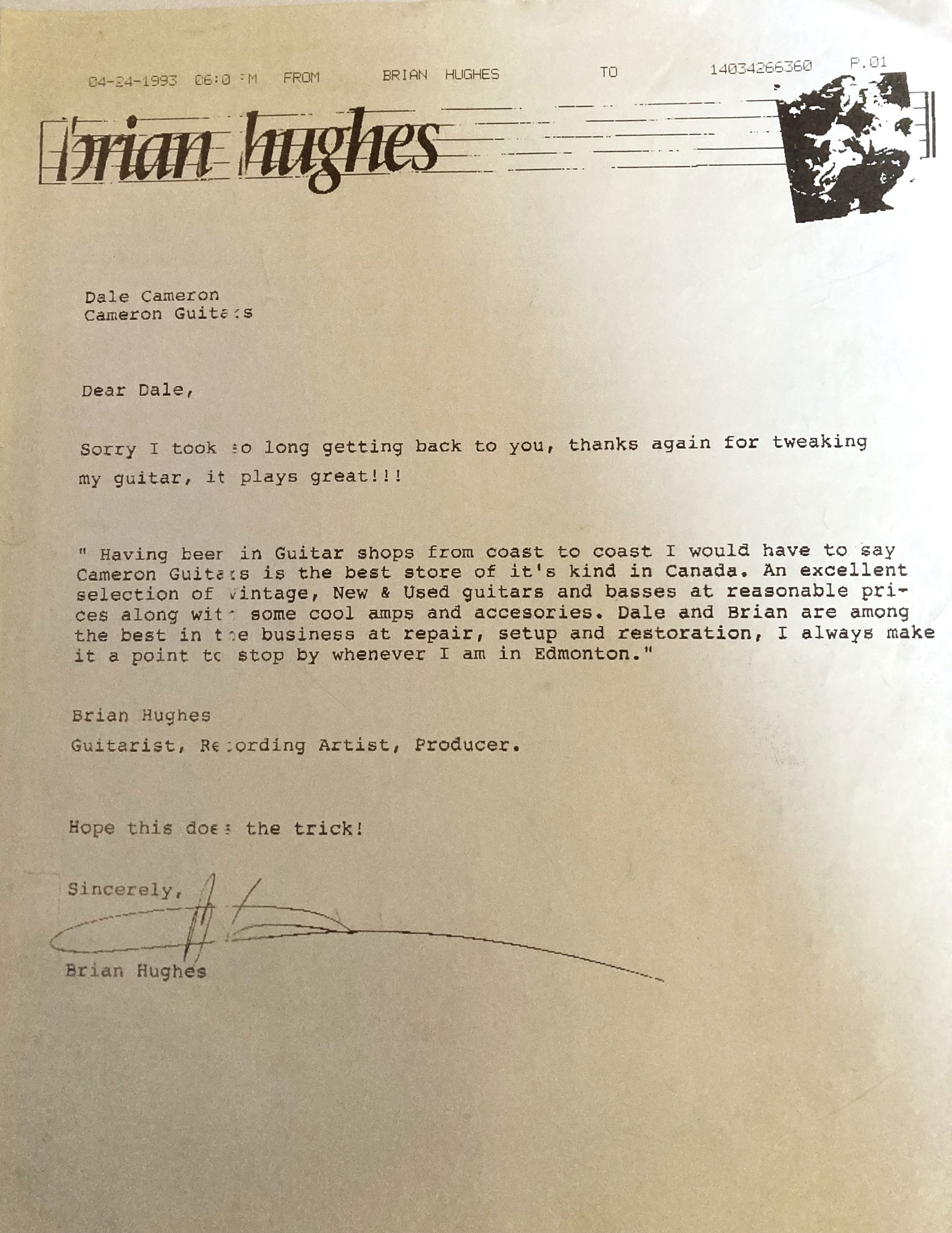

Brian Hughes, Canadian recording guitarist of smooth jazz and Latin music. Also a producer and guitarist for Loreena McKennitt. Set-up, fret dress ES-175 if I recall correctly.

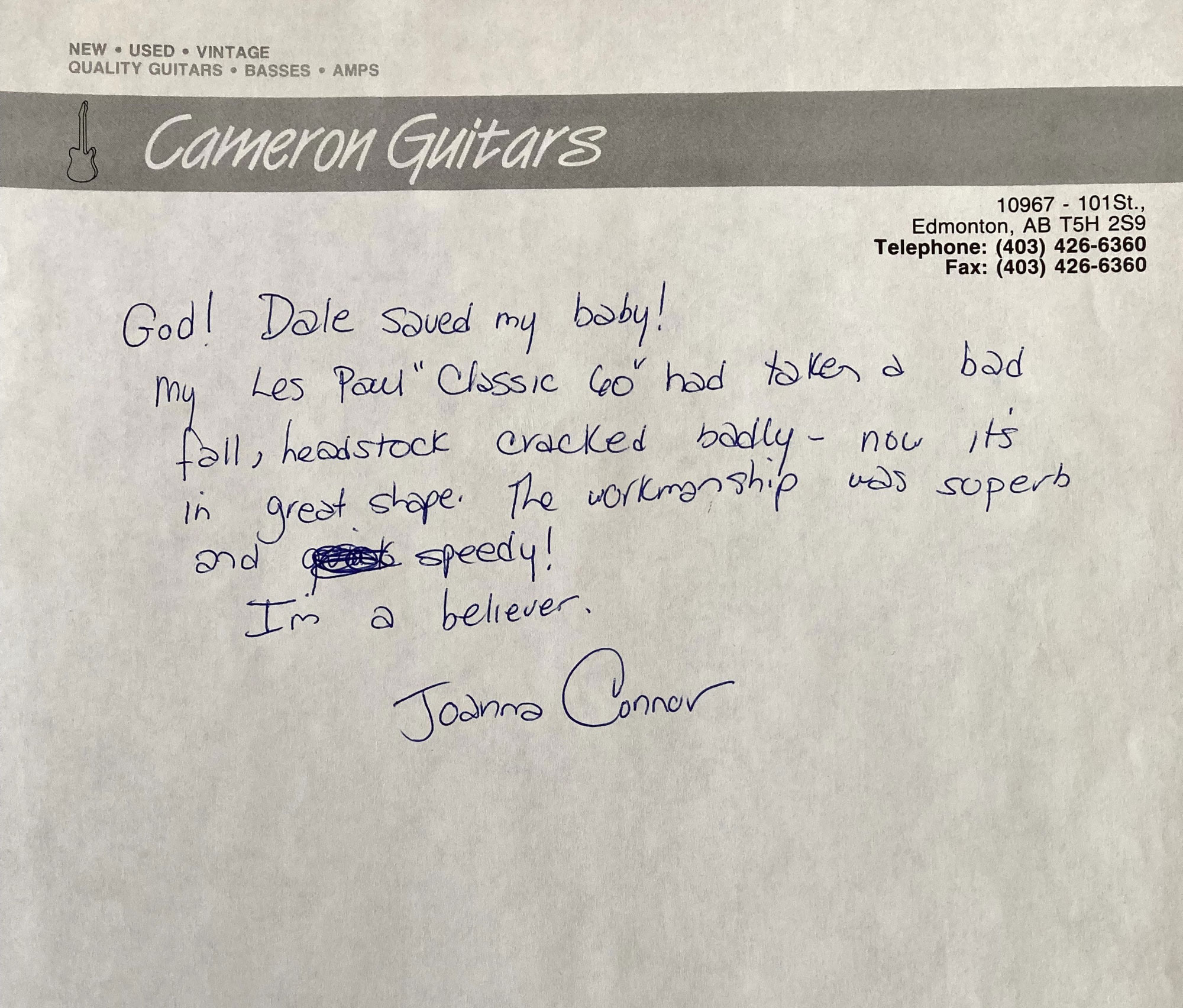

Joanna Connor, longtime Chicago blues player. Les Paul Classic 60, broken headstock expedited repair so she could continue playing on the road. Latest album ‘Best of Me’, produced by Joe Bonamassa.

Name withheld, replaced bass bout, rim, with book matched Brazilian rosewood, 1942 000 45. Dress fingerboard, fret and refinish on one of the last pre-war 000 45’s.

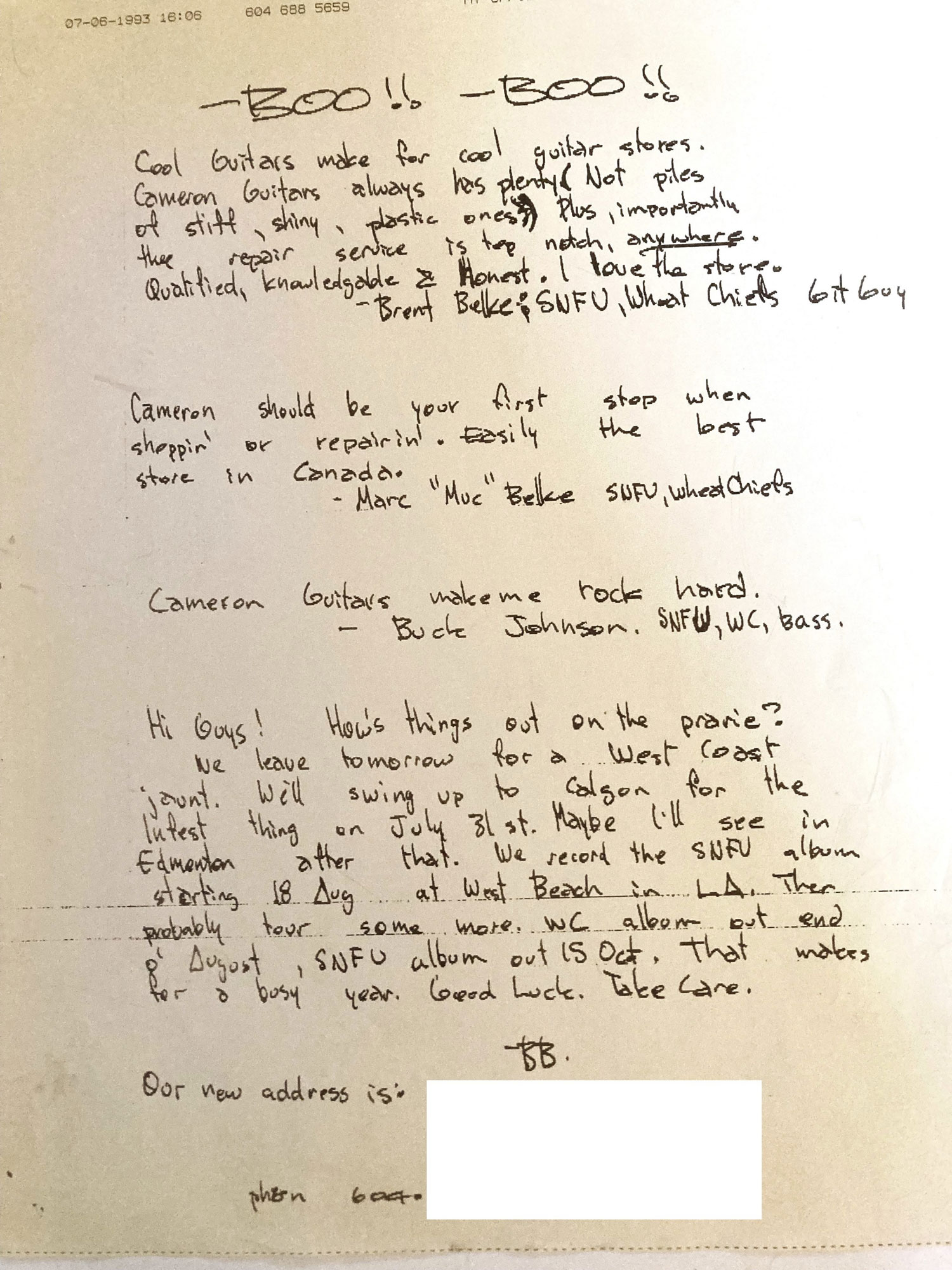

Brent Belke, Marc Belke, SNFU and Wheat Chiefs. Various repairs for the band.

Lester Quitzau, a long time Canadian blues guitarist. Martin D18, fret dress and set- up and a 50s Fender Stratocaster fret dress and set-up.

Bobby Cairns, guitarist, recording artist, composer, educator and long time member of the Tommy Banks band. Gibson ES 175, if I recall correctly, fret dress and set-up.

Greg Lake, of Emerson, Lake & Palmer, replaced fingerboard, frets on Zemaitis 12 string acoustic, because it wasn’t playing in tune.

Emmylou Harris, Gibson J-200 maple, emergency pick-up repair while rehearsing with the Edmonton Symphony Orchestra.

Red Shea, guitarist for Gordon Lightfoot, Ian and Sylvia’s Great Speckled Bird. Fret dress and set up Martin D45.

Long John Baldry Band, Fender P bass. Fret dress and setup.

PHOTOS

IN THE MEDIA

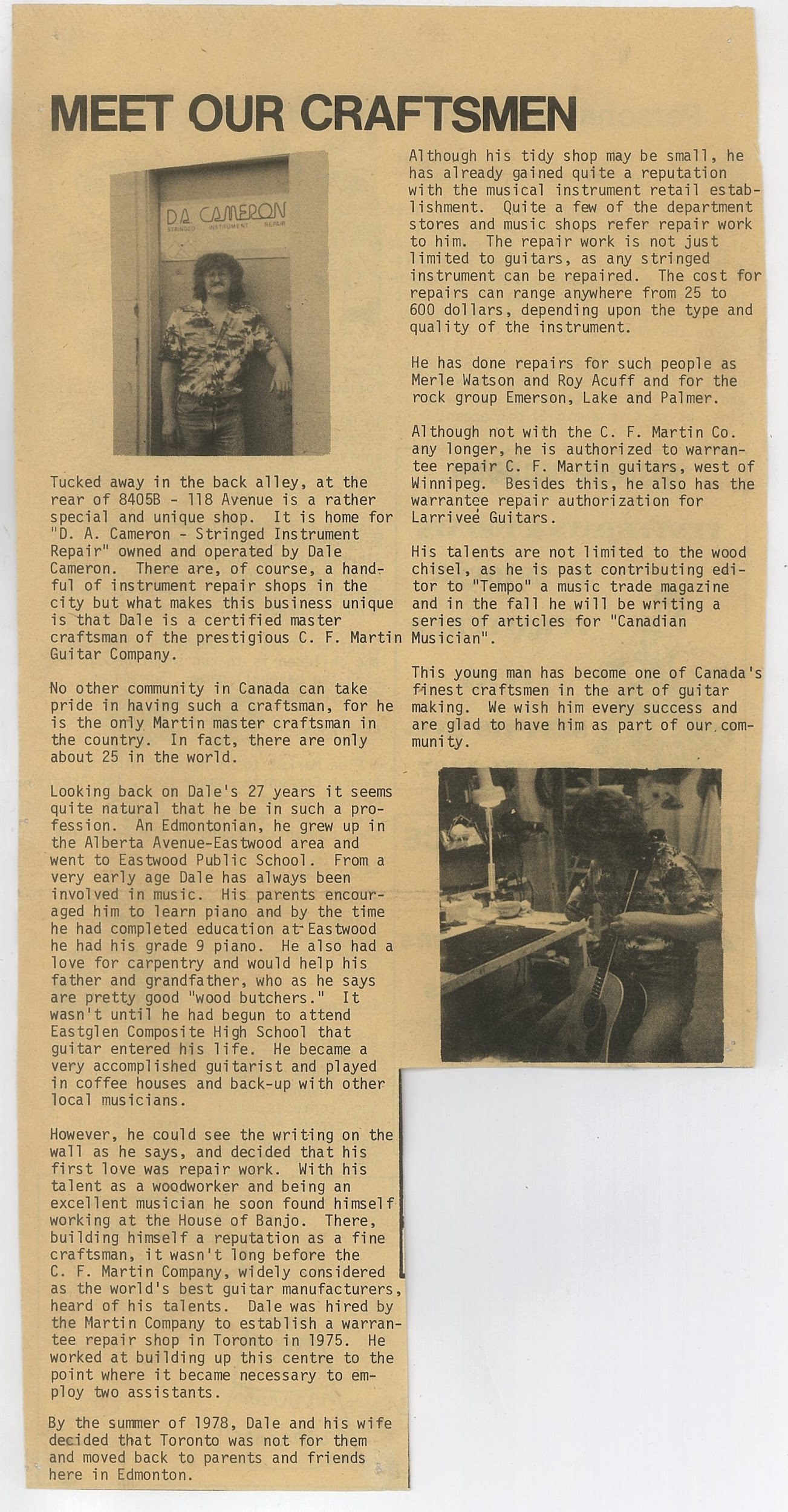

“Meet Our Craftsmen”

By Unknown, circa 1979

Tucked away in the back alley, at the rear of 8405B – 118 Avenue is a rather special and unique shop. It is home for “D.A. CAMERON – Stringed Instrument Repair” owned and operated by Dale Cameron. There are, of course, a handful of instrument repair shops in the city [of Edmonton] but what makes this business unique is that Dale is a certified master craftsman of the prestigious C. F. Martin Guitar Company.

No other community in Canada can take pride in having such a craftsman, for he is the only Martin master craftsman in the country. In fact, there are only about 25 in the world.

Looking back on Dale’s 27 years it seems quite natural that he be in such a profession. An Edmontonian, he grew up in the Alberta Avenue-Eastwood area and went to Eastwood Public School. From a very early age Dale has always been involved in music. His parents encouraged him to learn piano and by the time he had completed education at Eastwood he had his grade 9 piano. He also had a love for carpentry and would help his father and grandfather, who as he says are pretty good “wood butchers.” It wasn’t until he had begun to attend Eastglen Composite High School that guitar entered his life. He became a very accomplished guitarist and played in coffee houses and back-up with other local musicians.

However, he could see the writing on the wall as he says, and decided that his first love was repair work. With his talent as a woodworker and being an excellent musician he soon found himself working at the House of Banjo. There, building himself a reputation as a fine craftsman, it wasn’t long before the C. F. Martin Company, widely considered as the world’s best guitar manufacturers, heard of his talents. Dale was hired by the Martin Company to establish a warrantee repair shop in Toronto in 1975. He worked at building up this centre to the point where it became necessary to employ two assistants.

By the summer of 1978, Dale and his wife decided that Toronto was not for them and moved back to their parents and friends here in Edmonton.

Although his tidy shop may be small, he has already gained quite a reputation with the musical instrument retail establishment. Quite a few of the department stores and music shops refer repair work to him. The repair work is not just limited to guitars, as any stringed instrument can be repaired. The cost for repairs can range anywhere from 25 to 600 dollars, depending upon the type and quality of the instrument.

He has done repairs for such people as Redd Volkert, Martin Simpson, Roy Acuff and for the rock group Emerson, Lake and Palmer; and many others too numerous to mention.

Although not with the C. F. Martin Co. any longer, he is authorized to warrantee repair C. F. Martin guitars, west of Winnipeg.

His talents are not limited to the wood chisel, as he is past contributing editor to “Tempo” a music trade magazine and in the fall he will be writing a series of articles for “Canadian Musician”.

This young man has become one of Canada’s finest craftsmen in the art of guitar making. We wish him every success and are glad to have him as part of our community.

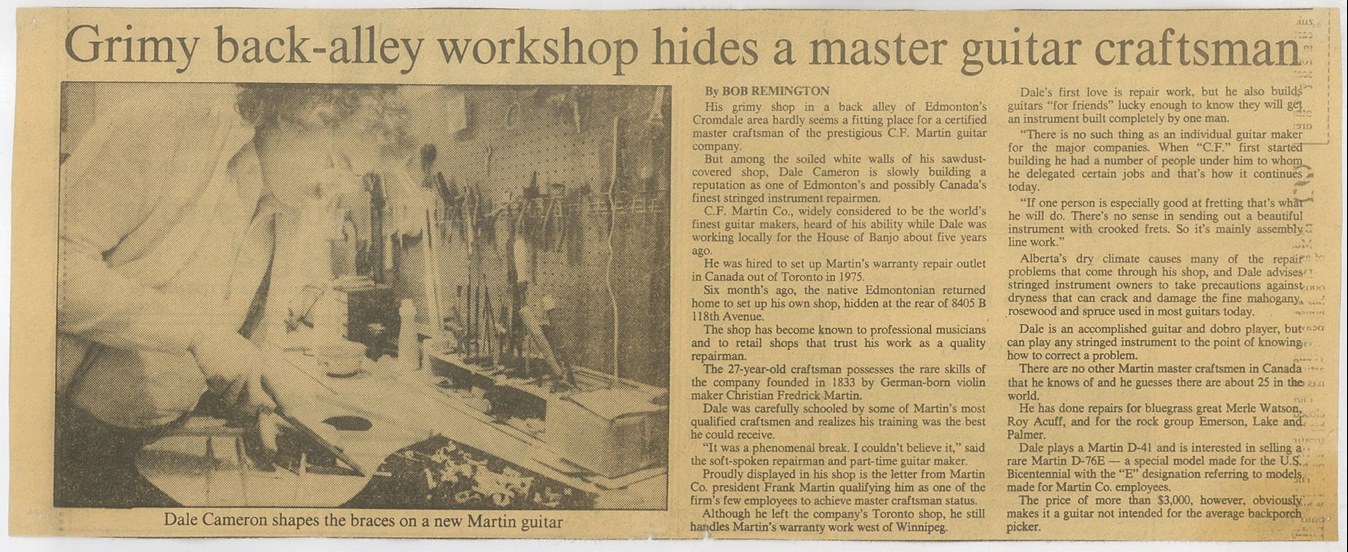

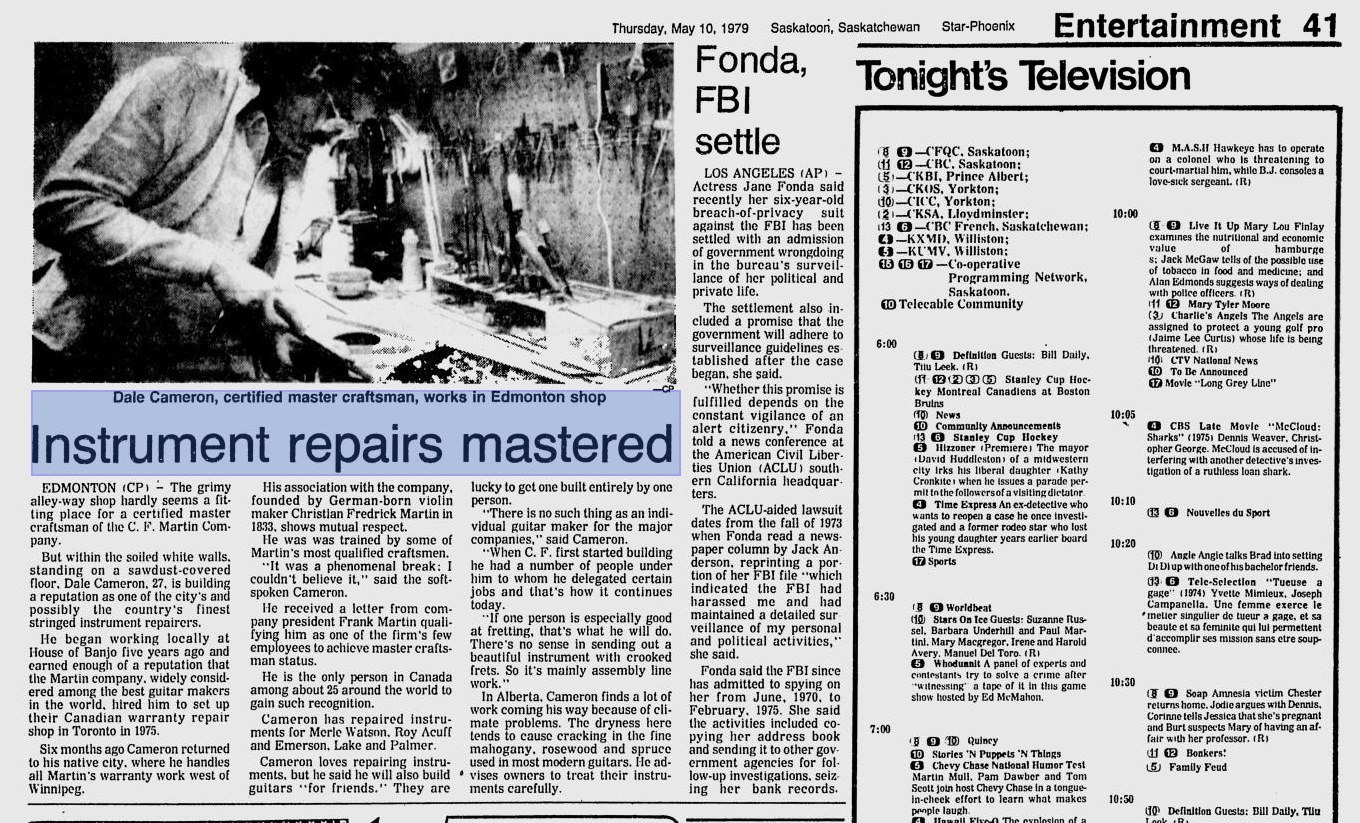

“Grimy back-alley workshop hides a master guitar craftsman”

By BOB REMINGTON

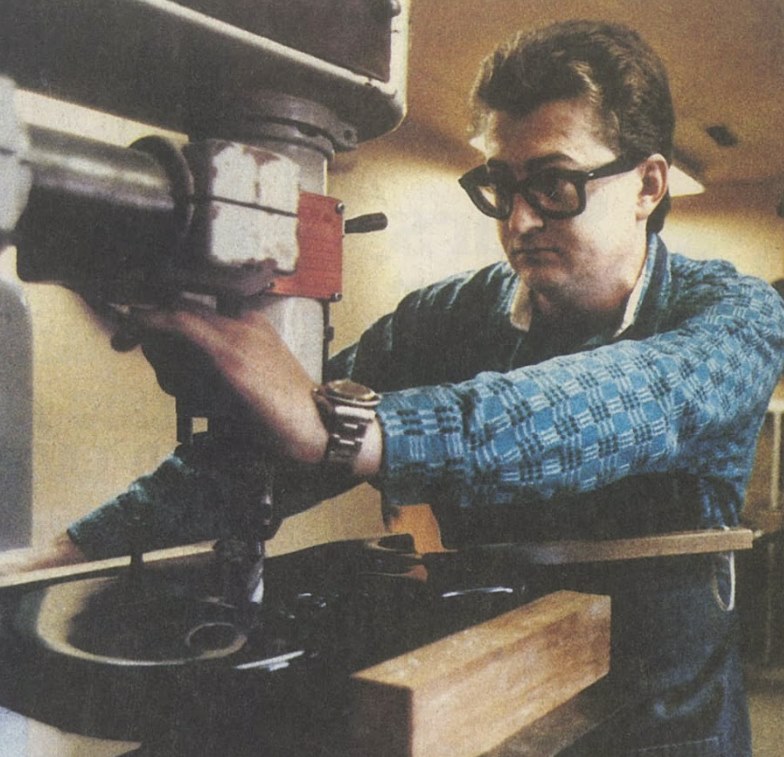

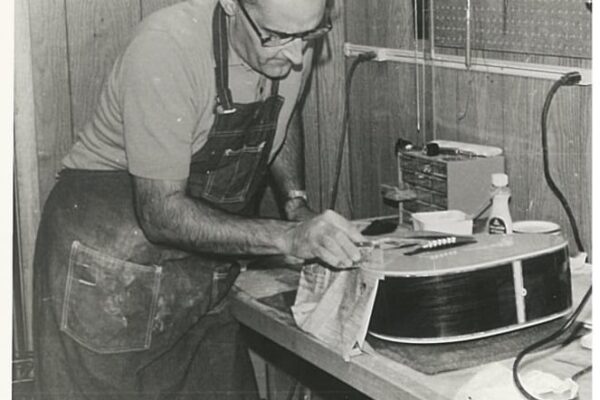

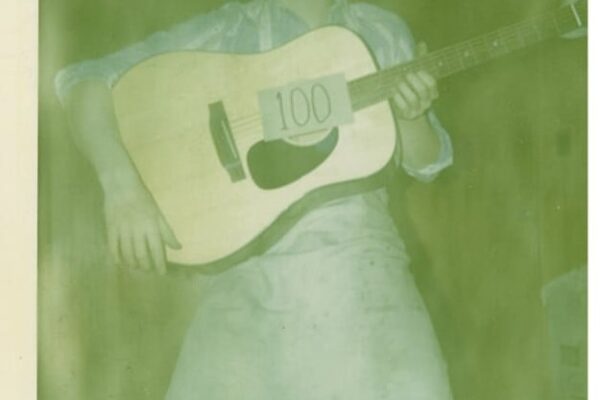

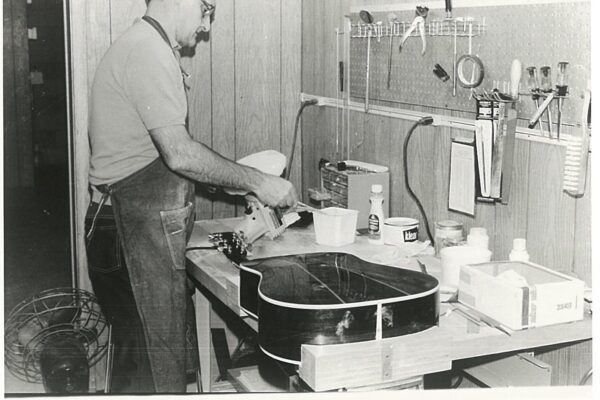

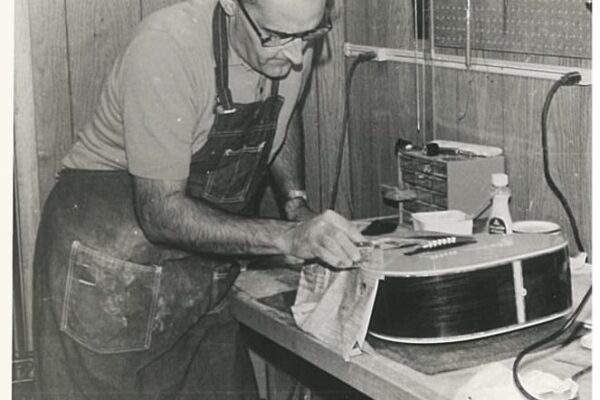

Caption: Dale Cameron shapes the braces on a new Martin guitar

His grimy shop in a back alley of Edmonton’s Cromdale area hardly seems a fitting place for a certified master craftsman of the prestigious C.F. Martin guitar company.

But among the soiled white walls of his sawdust-covered shop, Dale Cameron is slowly building a reputation as one of Edmonton’s and possibly Canada’s finest stringed instrument repairmen.

C.F. Martin Co., widely considered to be the world’s finest guitar makers, heard of his ability while Dale was working locally for the House of Banjo about five years ago.

He was hired to set up Martin’s warranty repair outlet in Canada out of Toronto in 1975.

Six months ago, the native Edmontonian returned home to set up his own shop, hidden at the rear of 8405 B 118th Avenue.

The shop has become known to professional musicians and to retail shops that trust his work as a quality repairman.

The 27-year-old craftsman possesses the rare skills of the company founded in 1833 by German-born violin maker Christian Fredrick Martin.

Dale was carefully schooled by some of Martin’s most qualified craftsmen and realizes his training was the best he could receive.

“It was a phenomenal break. I couldn’t believe it,” said the soft-spoken repairman and part-time guitar maker.

Proudly displayed in his shop is the letter from Martin Co. president Frank Martin qualifying him as one of the firm’s few employees to achieve master craftsman status.

Although he left the company’s Toronto shop, he still handles Martin’s warranty work.

Dale’s first love is repair work, but he also builds guitars “for friends” lucky enough to know they will get an instrument built completely by one man.

“There is no such thing as an individual guitar maker for the major companies. When “C.F.” first started building he had a number of people under him to whom he delegated certain jobs and that’s how it continues today.

“If one person is especially good at fretting, that’s what he will do. There’s no sense in sending out a beautiful instrument with crooked frets. So it’s mainly assembly line work.”

Alberta’s dry climate causes many of the repair problems that come through his shop, and Dale advises stringed instrument owners to take precautions against dryness that can crack and damage the fine mahogany, rosewood and spruce used in most guitars today.

Dale is an accomplished guitar and dobro player, but can play any stringed instrument to the point of knowing how to correct a problem.

There are no other Martin master craftsmen in Canada that he knows of and he guesses there are about 25 in the world.

He has done repairs for Redd Volkert, Martin Simpson, Roy Acuff, and for the rock group Emerson, Lake and Palmer and numerous other artists.

Dale plays a Martin D-41 and is interested in selling a. rare Martin D-76E – a special model made for the U.S. Bicentennial with the “E” designation referring to models made for Martin Co. employees.

“Specialists instrumental in giving music a new life”

By BARNABY PAGE

Journal Staff Writer

Edmonton Journal, circa June 1985

Caption: Instrument repairman Dale Cameron … works with acoustic and electric guitars

Nobody ever said music was a safe business; but the bullet holes in the country girl’s guitar were more than instrument repairman Dale Cameron had bargained for.

“She was missed, but the guitar was hit,” Cameron recalls of the music-hating husband’s deed. “I never knew the details.”

Indeed, farms and farmyards seem to spell nothing but trouble for musical instruments.

Aime Dery, an instrument craftsman who specializes in pianos and player pianos, observes that “people purchase player pianos in a granary, take the dead mice out of them, and refurbish them.”

Dery, and Cameron, whose experience includes the repair of medieval and Middle Eastern stringed instruments, are two of a hidden crowd of city instrument technicians dealing in the weird and the wonderful.

The more arcane aspects of their business take a back seat to standard repair work on the two tried-and-true favorites, piano and guitar. But the backroom business in obscure instruments is surprisingly extensive. <…>

A particular problem in Edmonton is the cracking of wood in the dry climate. <…> Cameron, who works with acoustic and electric guitars as well as more esoteric stringed instruments, says there are two types of instrument-owners.

“There are those that ignore them altogether, and those that are really particular about them.”

Those that ignore them tend also to be lax about insurance, he says, because insurance of an instrument usually needs a rider on the policy.

“People don’t think they need a rider. But if they’re using the thing professionally and it’s out of the house a lot they should. It’s probably a good idea if it’s an instrument over $800.”

The worst salvageable instrument Cameron has ever seen was a mandolin in Nazareth, Penn., where he studied at the workshops of Martin Guitar. It has been dropped overboard a lake boat, and “just gone to the bottom and been rescued.”

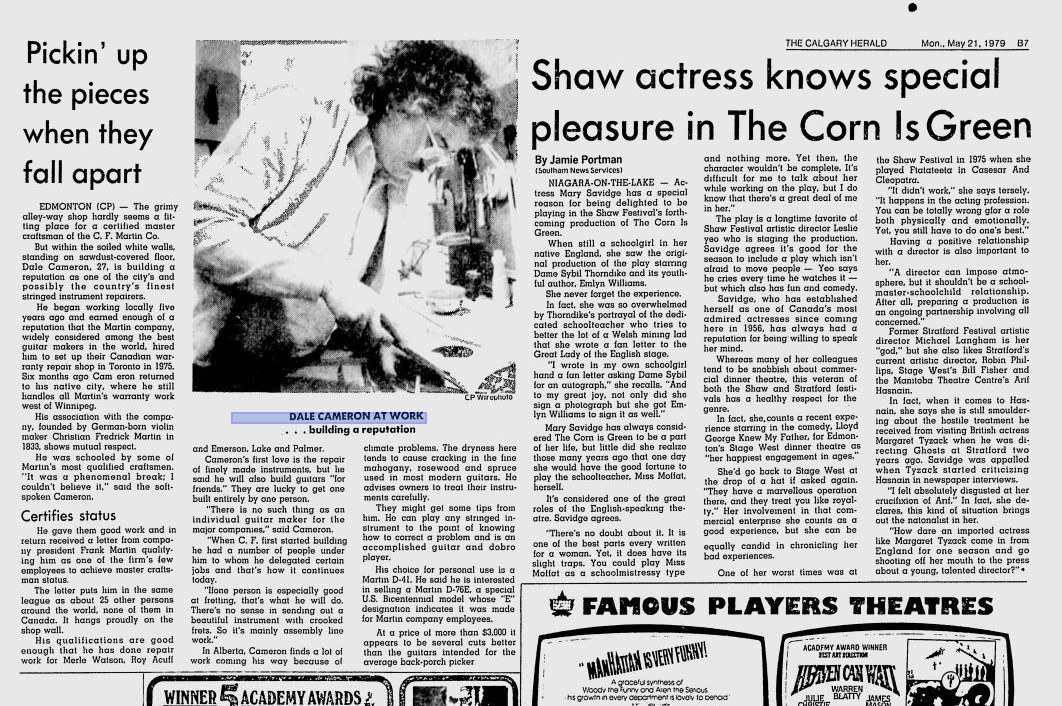

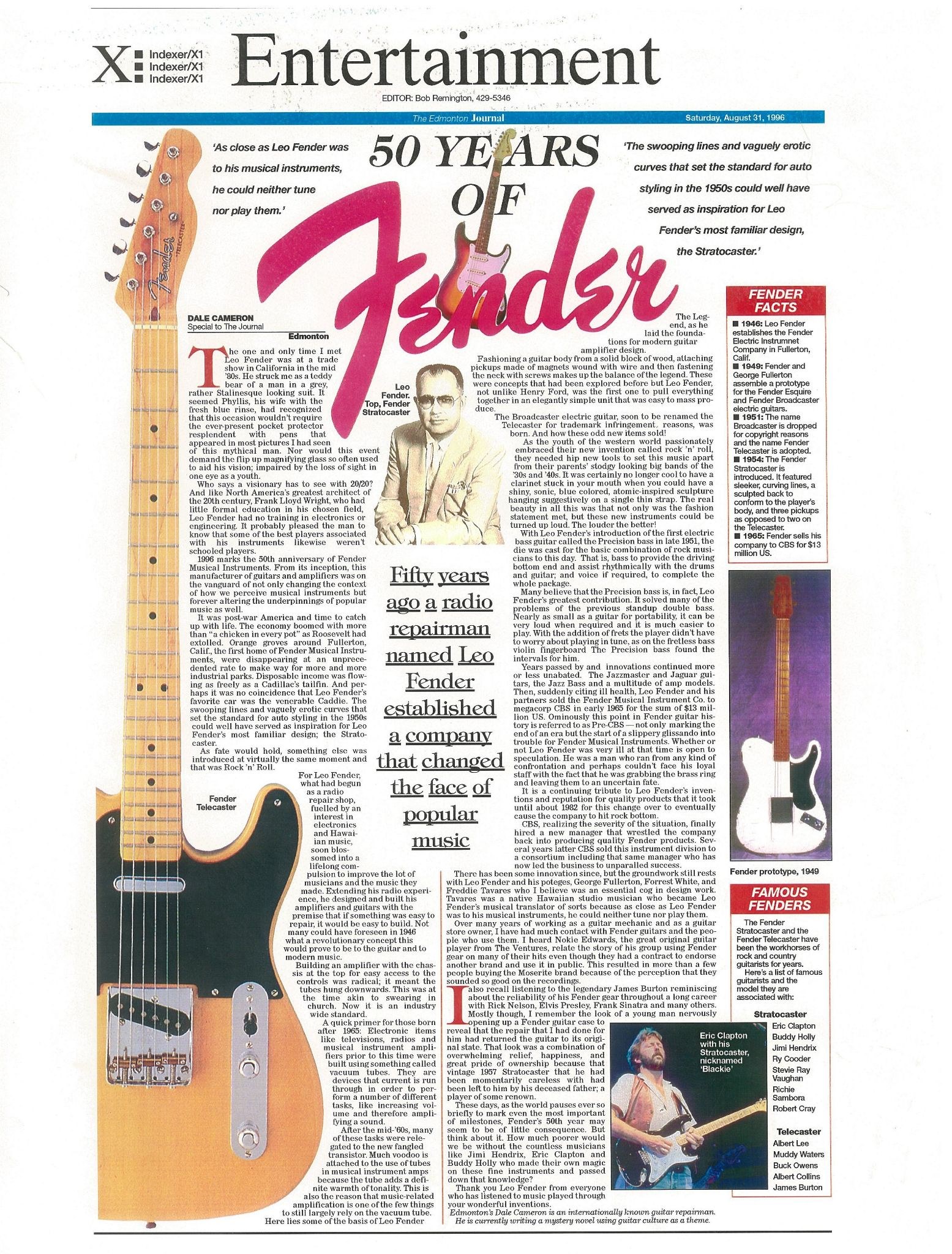

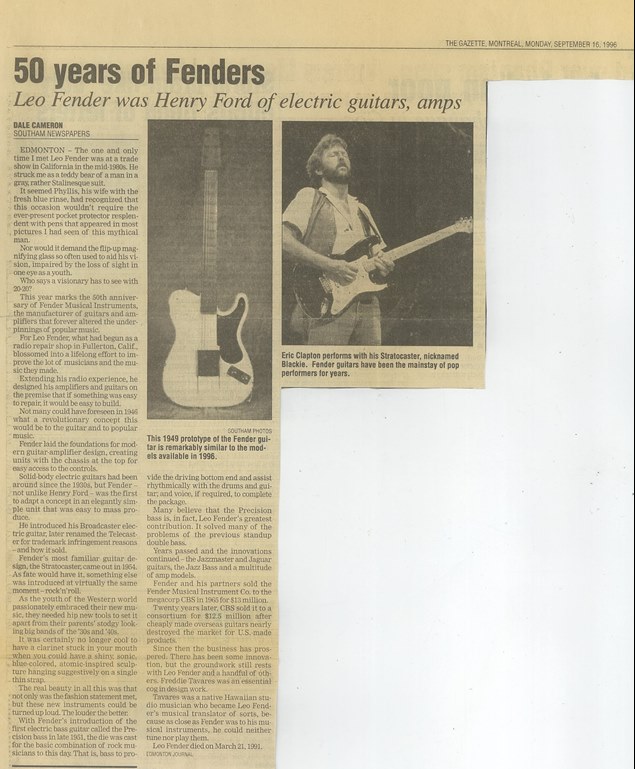

“50 Years of Fender”

Special to the Journal

Edmonton Journal, Aug. 31, 1996

The one and only time I met Leo Fender was at a trade show in California in the mid ‘80s. He struck me as a teddy bear of a man in a grey, rather Stalinesque looking suit. It seemed Phyllis, his wife with the fresh blue rinse, had recognized that this occasion wouldn’t require the ever-present pocket protector resplendent with pens that appeared in most pictures I had seen of this mythical man. Nor would this event demand the flip up magnifying glass so often used to aid his vision; impaired by the loss of sight in one eye as a youth.

Who says a visionary has to see with 20/20? And like North America’s greatest architect of the 20th century, Frank Lloyd Wright, who has little formal education in his chosen field, Leo Fender had no training in electronics or engineering. It probably pleased the man to know that some of the best players associated with his instruments likewise weren’t schooled players.

1996 marks the 50th anniversary of Fender Musical Instruments. From its inception, this manufacturer of guitars and amplifiers was on the vanguard of not only changing the context of how we perceive musical instruments but forever altering the underpinnings of popular music as well.

It was post-war America and time to catch up with life. The economy boomed with more than “a chicken in every pot” as Roosevelt had extolled. Orange groves around Fullerton, Calif., the first home of Fender Musical Instruments, were disappearing at an unprecedented rate to make way for more and more industrial parks. Disposable income was flowing as freely as a Cadillac’s tailfin. And perhaps it was no coincidence that Leo Fender’s favorite car was the venerable Caddie. The swooping lines and vaguely erotic curves that set the standards for auto styling in the 1950s could well have served as inspiration for Leo Fender’s most familiar design; the Stratocaster.

Who says a visionary has to see with 20/20?

As fate would hold, something else was introduced at virtually the same moment and that was Rock ‘n’ Roll.

For Leo Fender, what had begun as a radio repair shop, fuelled by an interest in electronics and Hawaiian music, soon blossomed into a lifelong compulsion to improve the lot of musicians and the music they made. Extending his radio experience, he designed and built his amplifiers and guitars with the premise that if something was easy to repair, it would be easy to build. Not many could have foreseen in 1946 what a revolutionary concept this would prove to be to the guitar and to modern music.

Building an amplifier with the chassis at the top for easy access to the controls was radical; it meant the tubes hung downwards. This was at the time akin to swearing in church. Now it is an industry-wide standard.

A quick primer for those born after 1965: Electronic items like televisions, radios and musical instrument amplifiers prior to this time were built using something called vacuum tubes. They are devices that current is run through in order to perform a number of different tasks, like increasing volume and therefore amplifying a sound.

After the mid-’60s, many of these tasks were relegated to the new fangled transistor. Much voodoo is attached to the use of tubes in musical instrument amps because the tube adds a definite warmth of tonality. This is also the reason that music-related amplification is one of the few things to still largely rely on the vacuum tube. Here lies some of the basis of Leo Fender The Legend, as he laid the foundations for modern guitar amplifier design.

‘The swooping lines and vaguely erotic curves that set the standard for auto styling in the 1950s could well have served as inspiration for Leo Fender’s most familiar design, the Stratocaster.’

Fashioning a guitar body from a solid block of wood, attaching pickups made of magnets wound with wire and then fastening the neck with screws makes up the balance of the legend. These were concepts that had been explored before but Leo Fender, not unlike Henry Ford, was the first one to pull everything together in an elegantly simple unit that was easy to mass produce.

The Broadcaster electric guitar, soon to be renamed the Telecaster for trademark infringement reasons, was born. And how these odd new items sold!

As the youth of the western world passionately embraced their new invention called rock ‘n’ roll, they needed hip new tools to set this music apart from their parents’ stodgy looking big bands of the ‘30s and ‘40s. It was certainly no longer cool to have a clarinet stuck in your mouth when you could have a shiny, sonic, blue colored, atomic- inspired sculpture hanging suggestively on a single thin strap. The real beauty in all this was that not only was the fashion statement met, but these new instruments could be turned up loud. The louder the better!

Whether or not Leo Fender was very ill at the time is open to speculation.

With Leo Fender’s introduction of the first electric bass guitar called the Precision bass in late 1951, the die was cast for the basic combination of rock musicians to this day. That is, bass to provide the driving to the bottom end and assist rhythmically with the drums and guitar; and voice if required, to complete the whole package.

Many believe that the Precision bass is, in fact, Leo Fender’s greatest contribution. It solved many of the problems of the previous standup double bass. Nearly as small as a guitar for portability, it can be very loud when required and it is much easier to play. With the addition of frets the player didn’t have to worry about playing in tune, as on the fretless bass violin fingerboard. The Precision bass found the intervals for him.

Years passed by and innovations continued more or less unabated. The Jazzmaster and Jaguar guitars, the Jazz Bass, and a multitude of amp models. Then, suddenly citing ill health, Leo Fender and his partners sold the Fender Musical Instrument Co. to megacorp CBS in early 1965 for the sum of $13 million US. Ominous this point in Fender guitar history is referred to as Pre-CBS — not only marking the end of an era but the start of a slippery glissando into trouble for Fender Musical Instruments. Whether or not Leo Fender was very ill at the time is open to speculation. He was a man who ran from any kind of confrontation and perhaps couldn’t face his loyal staff with the fact that he was grabbing the brass ring and leaving them to an uncertain fate.

It is a continuing tribute to Leo Fender’s inventions and reputation for quality products that it took until about 1982 for this change over to eventually cause the company to hit rock bottom.

CBS, realizing the severity of the situation, finally hired a new manager that wrestled the company back into producing quality Fender products. Several years later CBS sold this instrument division to a consortium including that same manager who has now led the business to unparalleled success.

There has been some innovation since, but the groundwork still rests with Leo Fender and his proteges, George Fullerton, Forrest White, and Freddie Tavares who I believe was an essential cog in design work. Tavares was a native Hawaiian studio musician who became Leo Fender’s musical translator of sorts because as close as Leo Fender was to his musical instruments, he could neither tune nor play them.

Over many years of working as a guitar mechanic and as a guitar store owner, I have had much contact with Fender guitars and the people who use them. I heard Nokie Edwards, the great original guitar player from The Ventures, relate the story of his group using Fender gear on many of their hits even though they had a contract to endorse another brand and use it in public. This resulted in more than a few people buying the Moserite brand because of the perception that they sounded so good on recordings.

I also recall listening to the legendary James Burton reminiscing about the reliability of his Fender gear throughout a long career with Rick Nelson, Elvis Presley, Frank Sinatra and many others. Mostly, though, I remember the look of a young man nervously opening up a Fender guitar case to reveal that the repair that I had done for him had returned the guitar to its original state. That look was a combination of overwhelming relief, happiness, and great pride of ownership because that vintage 1957 Stratocaster that he had been momentarily careless with had been left to him by his deceased father; a player of some renown.

These days, as the world pauses ever so briefly to mark even the most important of milestones, Fender’s 50th year may seem to be of little consequence. But think about it. How much poorer would we be without the countless musicians like Jimi Hendrix, Eric Clapton and Buddy Holly who made their own magic on these fine instruments and passed down that knowledge?

Thank you Leo Fender from everyone who has listened to music played through your wonderful inventions.

Edmonton’s Dale Cameron is an internationally known guitar repairman. He is currently writing a mystery novel using guitar culture as a theme.

Fender Facts

◼ 1946: Leo Fender establishes the Fender Electric Instrument Company in Fullerton, Calif.

◼ 1949: Fender and George Fullerton assemble a prototype for the Fender Esquire and Fender Broadcaster electric guitars.

◼ 1951: The name Broadcaster is dropped for copyright reasons and the name Fender Telecaster is adopted.

◼ 1954: The Fender Stratocaster is introduced. It featured sleeker, curving lines, a sculpted back to conform to the player’s body, and three pickups as opposed to two on the Telecaster.

◼ 1965: Fender sells his company to CBS for $13 million US.

Famous Fenders

The Fender Stratocaster and the Fender Telecaster have been workhorses of rock and country guitarists for years.

Here’s a list of famous guitarists and the model they are associated with:

Stratocaster

- Eric Clapton

- Buddy Holly

- Jimi Hendrix

- Ry Cooder

- Stevie Ray Vaughan

- Richie Sambora

- Robert Cray

Telecaster

- Albert Lee

- Muddy Waters

- Buck Owens

- Albert Collins

- James Burton

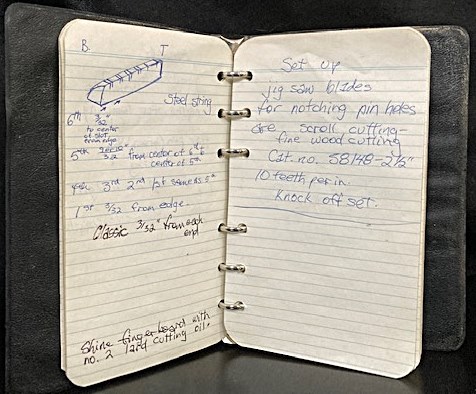

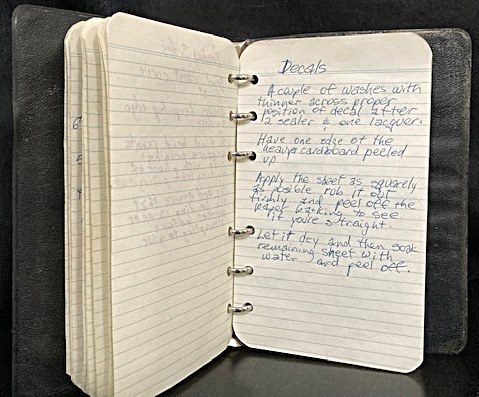

Dale's column in Tempo (a Canadian music industry monthly) circa the late 1970s. He was writing an editorial consultant for maintenance/repair.

Q: I own a twelve year old acoustic guitar that has a crack in the face from the rear of the bridge to the end block. I’d like to know if it can be repaired without altering the tone, and if so, how this should be done.

The crack in your instrument can be repaired, but I wouldn’t recommend that you attempt the repair work yourself. The trick with it is that every crack is different—only someone with a good deal of experience will be able to decide which method of repair is best in your case.

The method of repair will vary with the age of the crack itself. New hairline cracks are easier to repair than distinct separations, which are caused when the wood surrounding the crack is allowed to shrink over a period of time. The lower the humidity of course, the faster the wood will shrink.

These open, separated cracks must be repaired with a matching splint, glued into place. The hairline crack need only have glue run into it. First the crack is forced open, either with special jacks or by hand, if you can get your arm inside the guitar. Water is run into the crack so that the glue will be easier to work in, and then the glue is worked with the fingers. The excess glue is wiped off, and the crack is closed with special clamps.

If done properly, both of these procedures should leave the tonal quality of the instrument unharmed. I should also mention that until you have the guitar repaired, you should try and avoid running your fingers over the damaged area, since dirt and oil rubbed into the crack will have a bearing not only on the repair job itself, but also on how good the touch-up will appear.

— Dale Cameron, April 1977

“Nice guys don’t finish last”

By Alan Kellogg

Edmonton Journal, Sept. 1, 1994

As cynical as you can get about the music business, there remains a small, quiet, insistent voice way back there. Some of us still hear it.

If you’re genuinely talented, work hard and keep your nose clean, you’ll get your shot.

No one is suggesting the process will be easy or the rewards will be commensurate with the work and gift involved, but someone will listen, some day.

Take the case of Redd Volkaert.

Working out of Edmonton for years, plying his trade in the relative Canadian music industry hinterland, Redd (it doesn’t seem natural to call the man by his last name) finds himself a bona-fide Nashville session guitarist.

Redd’s a modest cuss, and he’ll be the first to tell you every new floor exposes another ceiling. He certainly hasn’t yet cracked the creamy upper reaches of the Music City Rolodex, the handful of players who get the top album work, day in and day out.

But after only a few years in Nashville, arriving as a total unknown, he’s managed to get off the grind of road work and enter the arcane circle of those who get it right the first time in the recording studio: the ones who get the phone calls. It’s a deal that allows Redd to enjoy his marriage and home in leafy Smyrna, Tenn., and concentrate on honing his craft. “I’m the luckiest guy in the world,” he says. He means it.

“Luck?” Dale Cameron of Cameron Guitars, a crusty, unsentimental observer of contemporary axemanship, says you don’t find many like Redd.

“He’s certainly the best country player to have ever come out of this town. He’s a real musician, it’s not contrived, it flows out of him.”

Born and raised in Vancouver, Redd got his first hand-me-down Harmony guitar at age 10 and took exactly two formal lessons. Son of a weekend R&B player, Redd landed his first gig at the age of 13 at the scenic KitKat club on East Hastings. By the time he left for Edmonton six years later, he’d already played every country dive and Legion hall in the Lower Mainland. Weddings, parties, ritual circumcisions, you name it.

Never one to complain, Redd can still let out a deep chuckle or two remembering his days studying at country music grade school…

The price of more than $3,000, however, obviously makes it a guitar not intended for the average backporch picker.

MEMORIES

The Sharpest Tool in the Box

Fashioned from a worn out file ground smooth in all dimensions, the bevel is hollow ground and then honed to a 25 degree angle as shown in this helpful video:

I prefer to use a honing guide rather than free hand but see which you like best. Hollow ground chisels of this width, 1 inch, are the best for removing bridges without scaring the surrounding top.

The handle is white oak and after 45 years shows hard and much loved use. I apply the same technique for sharpening hand plane blades.

A Smashed Ukulele

This uke was handed to me by a newly hired supposed guitar tech who, I soon learned, was gunning for my position. This individual had no formal training, so needless to say our interactions were adversarial from the start.

On top of this, he was joining Martin alongside another new hire, a boss who came from marketing and had no grasp of the musical instrument business. (Neither lasted— seven months later they were both unceremoniously fired.)

The challenge of this ukulele was that the body was crushed flat when someone sat on it years earlier. The so-called tech passed off the challenge to me with the idea that, “if you’re so damn good, let’s see if you can repair this!”

I think you can judge this for yourself by looking at the finished job in these photos! I’m really happy that my wonderful granddaughter is the current owner of a rather memorable piece of my career.

The last photo is of my granddaughter and I with her restored 1950s Martin uke several years ago.

Coincidence

In 1975 I was at the old Martin Guitar factory doing my first training with Donald Dech. The first delivery of Sigma guitars came in and I was assigned the job of buffing the guitars as their appearance was dull. Chris Martin IV, Donald Dech and I opened the shipment to examine the guitars. Donald and Chris talked it over and considered ways to improve the quality of the guitars.

I loosened the strings on one of the Sigma guitars, so that Donald could insert his whole forearm into the sound hole and scallop the braces with his pocket knife. A valuable lesson for me, learning the trick to getting your arm inside the sound hole. Many years later, Robin Hunter, a former employee of mine at Cameron Guitars, relived the same conversation with C.F. Martin IV when touring the Nazareth factory.

The old factory had 2” by 10” treads on the stairs to the second floor that were halfway worn through.

Re: The Most memorable thank you letter received from a client via Martin Nazareth

This letter was forwarded to me from Martin Nazareth, from the owner of a guitar that I repaired. This guitar was damaged by an American alcoholic and very famous performer at a music festival in Ontario. I was at the festival, promoting Martin and the repair shop. The owner of the guitar invited “Mr. X” to jam in his motor home after the festival shut down for the night, being unaware of the nature of this person and how intoxicated he was, he allowed him to play his personal guitar. Mr. X took offence to something said and smashed the Brazilian rosewood D28 on a kitchen counter. Later that night I was sleeping in the Martin van and was awoken by the sounds of a siren. The next morning, the owner brought the guitar to me to inspect. He agreed to the repairs and handed the guitar over to me. He related the story to me, as to how the guitar was broken by Mr. X and the reason for the nocturnal ambulance. He had beat the daylights out of Mr. X.

I managed to do a mostly invisible repair to the guitar.

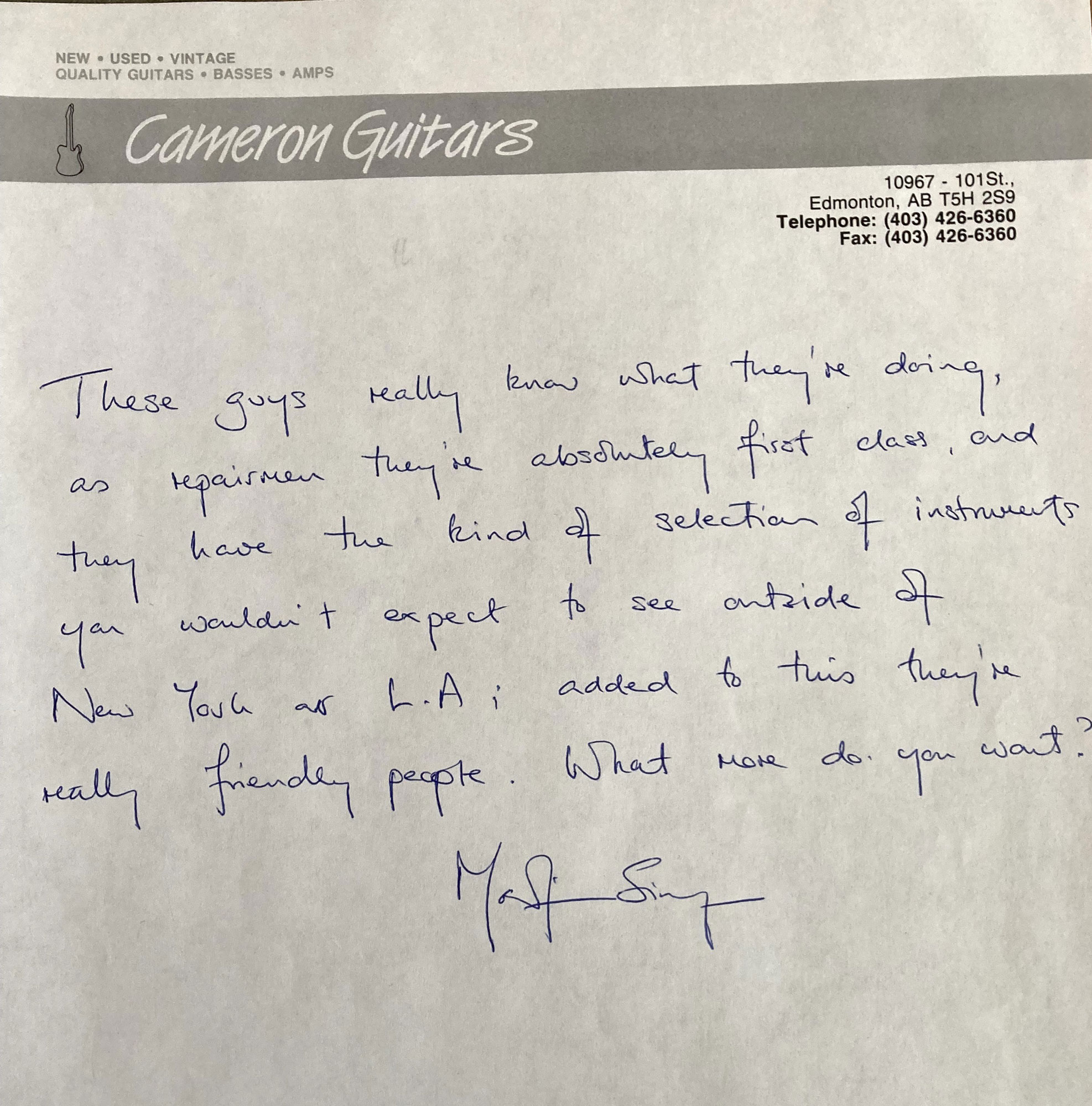

TESTIMONIALS & DEDICATIONS

Mike Longworth autographed a copy of his book titled “Martin Guitars, A History” for Dale on Sept. 9, 1990.

Dale writes, “My friend Mike Longworth was a very accomplished mother of pearl inlay practitioner. Mike was hired to be in charge of the reintroduction of the D45 and its variants in 1968. Mike visited us in Edmonton when he was invited to the Canadian Country Music Awards in the late 1980s.”

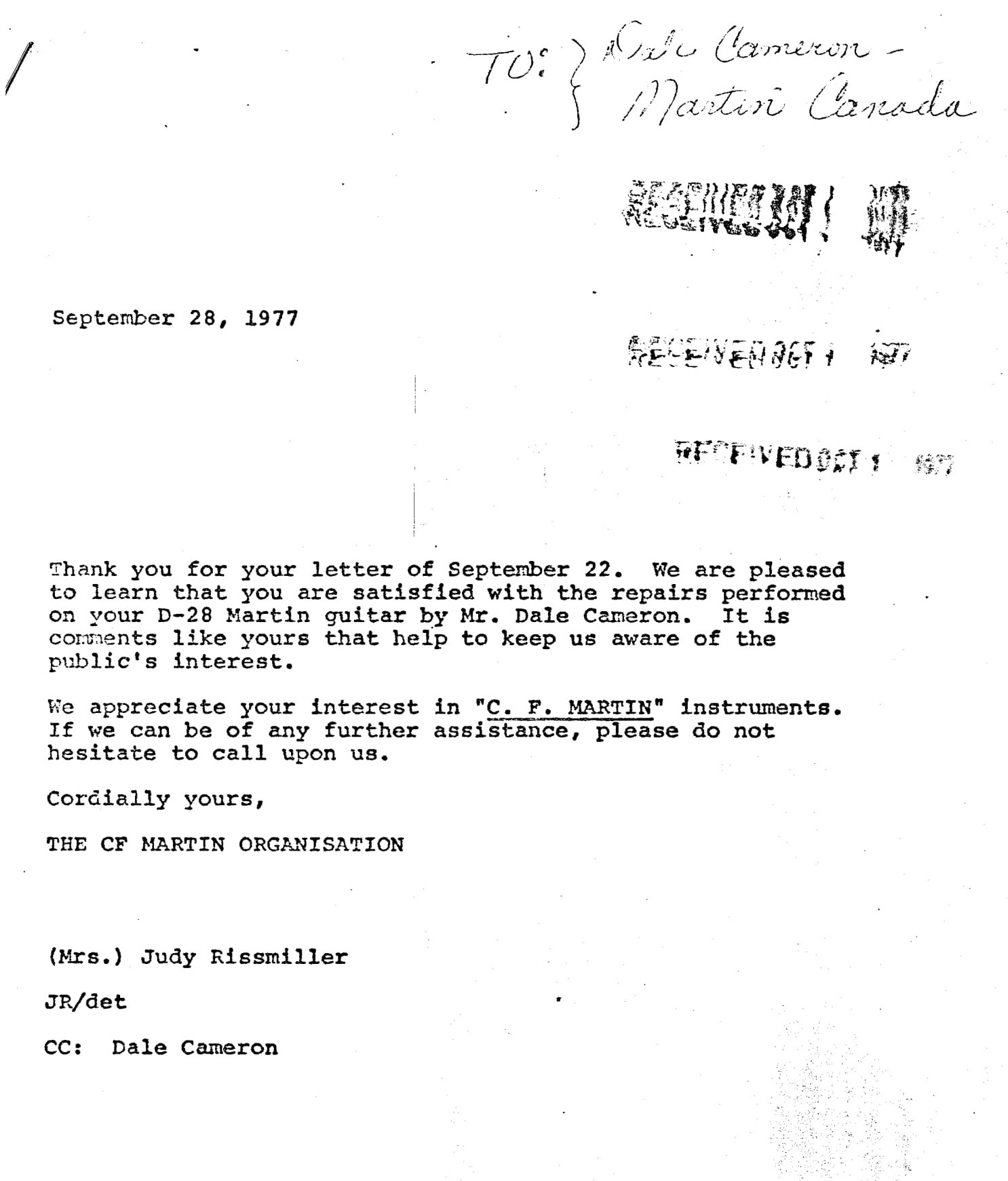

Thank you letter from Dale Cameron client Ken in September 1977 and reply from CF Martin Organization

Sept. 22, 1977

I recently had to have repairs made to my D28. I took it to your shop in Scarborough where Dale Cameron repaired it. It was quite a mess when I took it in, both treble and bass rims were cracked, the back was cracked, and the front had a dent in it.

I didn’t think it could be repaired, it was in mint condition before the accident.

Your man took my guitar and did an excellent job on it. I am very happy with it, the only mark still visible is a small spot on the face of it.

Thank you very much for making good men available to repair these fine instruments.

Sincerely, Ken

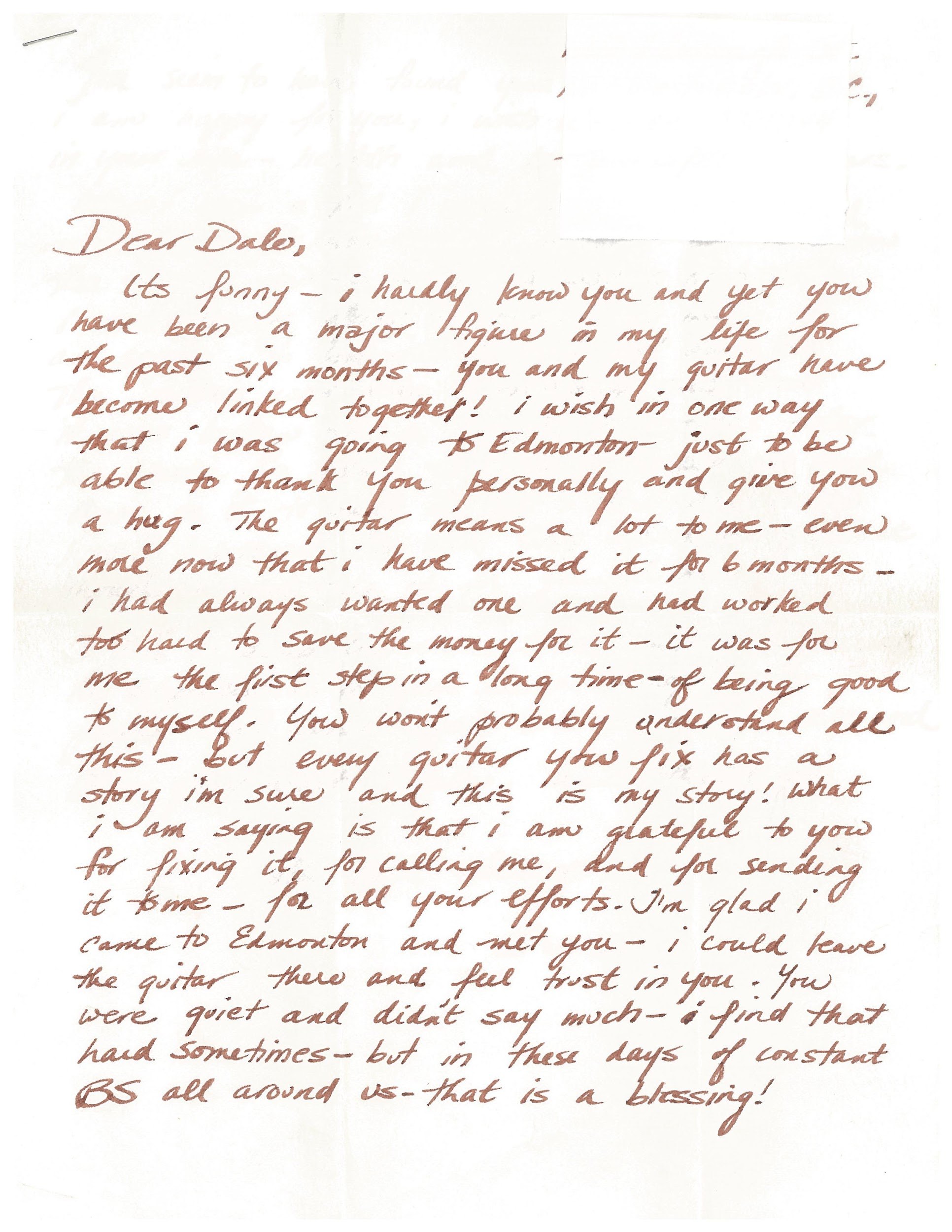

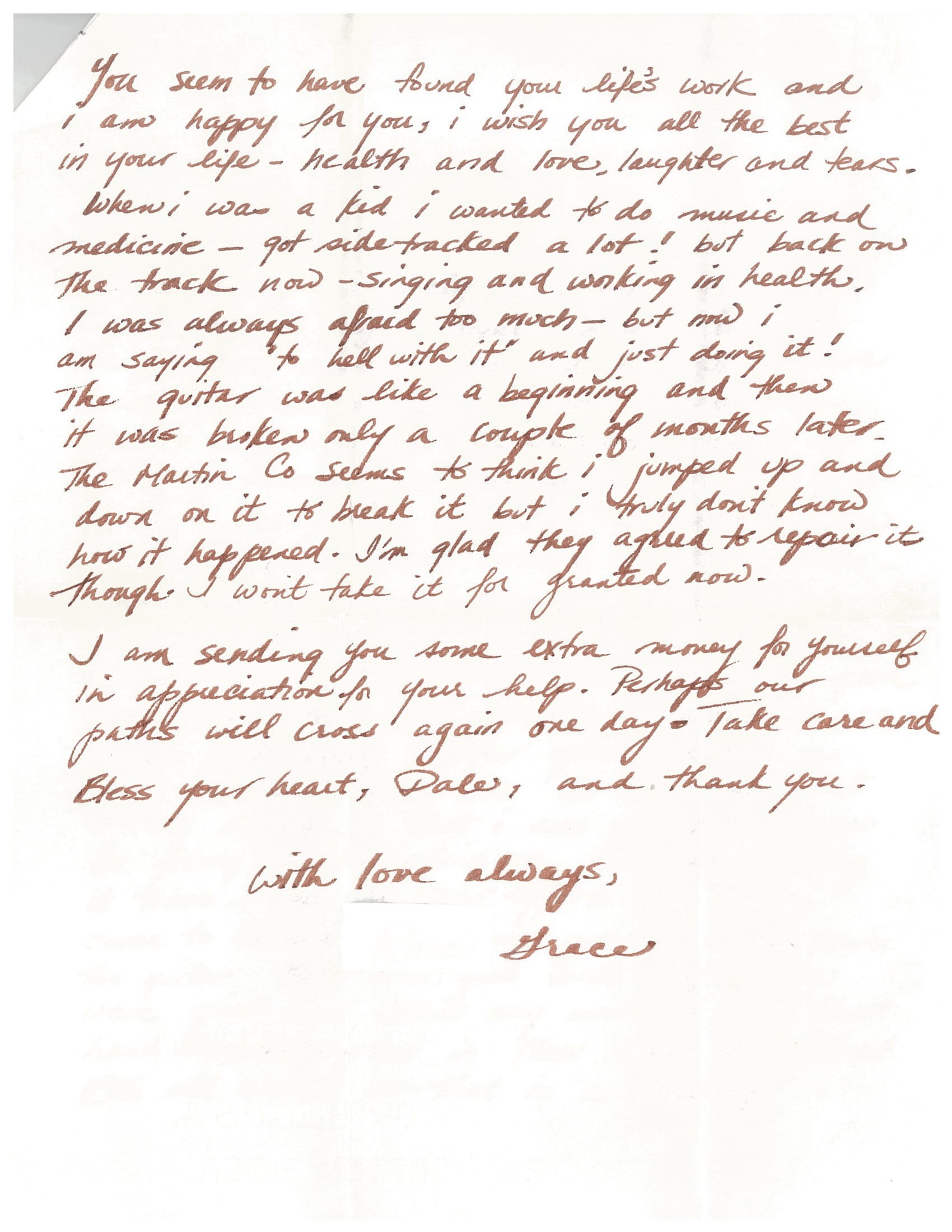

Undated thank you letter from Dale Cameron client Grace

Dear Dale,

It’s funny — I hardly know you and yet you have been a major figure in my life for the past six months — you and my guitar have

become linked together! I wish in one way that I was going to Edmonton just to be able to thank you personally and give you a hug. The guitar means a lot to me — even more now that I have missed it for 6 months — I had always wanted one and had worked too hard to save the money for it — it was for me the first step in a long time of being good to myself. You won’t probably understand all this — but every guitar you fix has a story I’m sure and this is my story! What I am saying is that I am

grateful to you for fixing it, for calling me, and for sending it to me — for all your efforts. I’m glad I came to Edmonton and met you — I could leave the guitar there and feel trust in you. You were quiet and didn’t say much — I find that hard sometimes — but in these days of constant BS all around us — that is a blessing!

You seem to have found your life’s work and I am happy for you. I wish you all the best in your life — health and love, laughter and tears. When I was kid I wanted to do music and medicine — got side tracked a lot! but back on the track now — singing and working in health, always afraid too much — but now I am saying “to hell with it” and just doing it!

The guitar was like a beginning and then it was broken only a couple of months later. The Martin Co. seems to think I jumped up and down on it to break it but I truly don’t know how it happened. I’m glad they agreed to repair it though I won’t take it for granted now.

I am sending you some extra money for yourself in appreciation for your help. Perhaps our paths will cross again one day. Take care and Bless your heart, Dale, and thank you.

With love always,

Grace

CORRESPONDENCE

Official authorization from W. E. Locke, Martin Organisation Canada Ltd, to do authorized repairs – circa the late 1970s.

THE MARTIN ORGANISATION CANADA LIMITED

80 Milner Ave., Unit 12, Scarborough M1S 3P8, Ontario, Canada • Phone 416-298-1794

D.A. Cameron Stringed Instruments

Repair

9315 – 95th St.,

Edmonton, Alberta

Dear Dale:

It is our pleasure to notify you that you have been authorized to perform warranty repairs on Martin guitars. Upon specific factory authorization for each warranty project, you may accomplish the needed repair and bill us according to the attached price schedule.

There may be an occasional warranty repair which is not covered by the schedule, or which is so extensive as to require a larger payment. In such a case, please give us advance notice of your requirements.

We feel this system will be mutually profitable, in addition to improving our customer service. If you have any questions in connection with this arrangement, please feel free to contact us.

Yours truly,

THE MARTIN ORGANISATION CANADA LIMITED

W.E. Locke

WEL/jb

Enclosures

Official letter from Frank H. Martin recognizing Dale Cameron as Master Craftsman – Oct. 18, 1977

THE CF MARTIN ORGANISATION

Box 329 Nazareth, Pennsylvania 18064 USA 215-759-2837 · Telex 831323

October 18, 1977

Mr. Dale Cameron

Products Service Manager

The Martin Organisation Canada Limited

80 Milner Avenue, Unit 12

Scarborough MlS 3P8

Ontario, CANADA

Dear Dale:

Occasionally the opportunity comes along to recognize an employee in a special way. An exclusive status is attained when a worker involved in guitar production or repair qualifies for the rank of Master Craftsman. Only about one out of ten workers ever joins this group.

A Master Craftsman must be one of Martin’s most technically skilled workers and must have demonstrated the potential for leadership. Also, a Craftsman should have enough service for the measurement of the above skills.

While the length of service necessary is usually around 5 years, it’s clear in your case, Dale, that when you started with Martin Canada in July of 1975, you had previous experience that was very helpful. So with this letter I’m very happy to add your name to the list of those employees recognized as Master Craftsmen.

Congratulations,

THE CF MARTIN ORGANISATION

Frank H. Martin

President

FHM/mrd

Official letter from Mike Longworth regarding Martin Canada warranty schedule – June 22, 1978

THE CF MARTIN ORGANISATION

Box 329 · Nazareth, Pennsylvania 18064 USA : 215-759-2837 – Telex 831323

June 22, 1978

Mr. Dale Cameron

The Martin Organisation Canada Limited

80 Milner Avenue, Unit 12

Scarborough, Ontario

CANADA MIS 3P8

Dear Dale:

We are pleased to advise you that we have updated our warranty payment schedule. A copy of the new schedule is enclosed herewith for your use. When performing warranty projects, you may bill us according to this schedule as of July 1, 1978.

Your assistance with the warranty program is greatly appreciated. It helps our customers to get their guitars repaired more quickly, and it also saves them shipping charges in many instances. It also is of direct assistance to us in that it cuts down the number of guitars which are actually returned to the factory in our overextended Repair Department.

We thank you for your help and hope to continue to enjoy a mutually satisfactory arrangement with you.

Cordially yours,

THE CF MARTIN ORGANISATION

Mike Longworth

ML/mrd

Enc.

OF INTEREST

Guitar Repair Checklist:

What to look for in a reputable repair shop

With 40+ years of experience, I can spot the warning signs a mile away and have billed many thousands of hours to reverse shoddy workmanship. Here is my list of things to look out for when seeking out qualified repairmen to handle your valuable instrument and avoid unnecessary damage.

- If you cherish your valuable instrument, do your homework about the guitar repair shop you plan to use. Check online reviews, ask around. If you don’t, be prepared to have a very bad day.

- Always record your serial number and photograph your guitar before and after the work is done.

- If the repair quote sounds inexpensive for the repair you require, then the work is likely going to reflect that.

- Ask to see a copy of the repairman’s credentials from a certified luthier school. Here’s a list of schools for the U.S., Canada, and international schools as compiled by the Guild of American Luthiers.

- Insist on seeing the shop or business front (for example, do they have the proper documentation and record keeping in place) with particular emphasis on the luthier tools, jigs and spray booth.

- Ask about warranty and insurance coverage that the repair shop has to cover you in case of a theft from the repair facility.